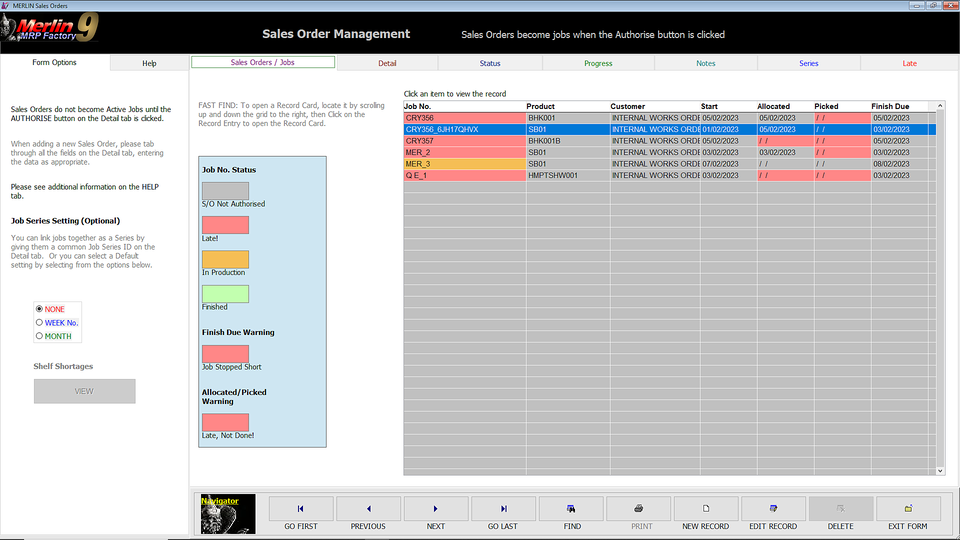

2: Creating a Sales Order

Click the NEW RECORD button, and you will be taken to the Input Screen.

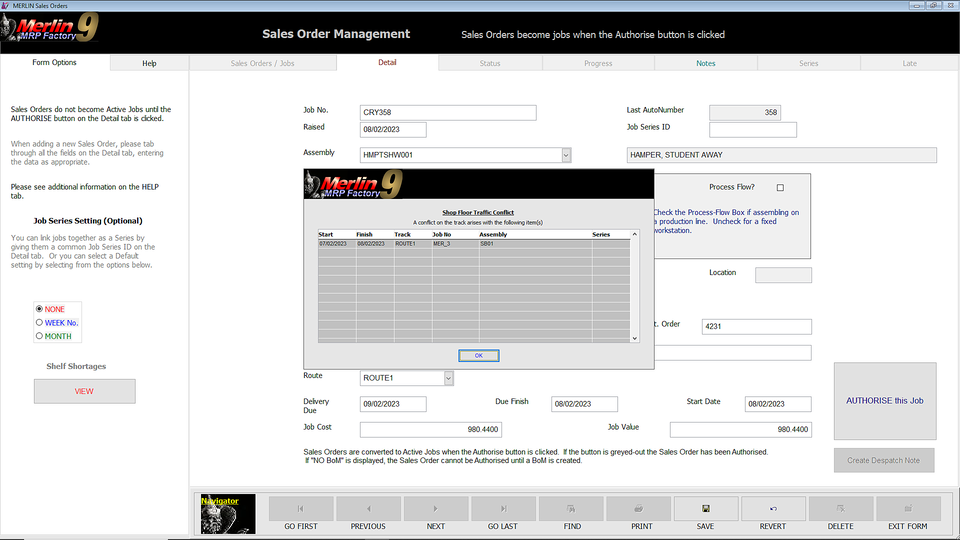

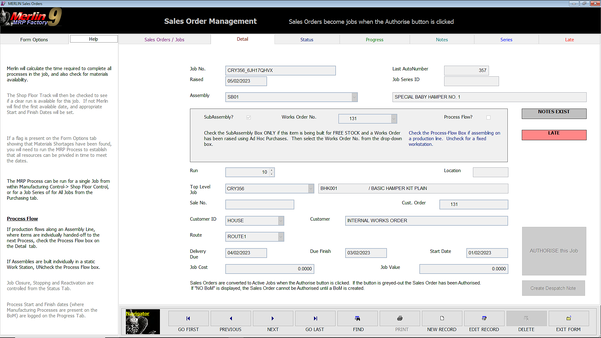

Enter the information as required. The Job No. will be autocreated by the Merlin MRP System, as will the Raised Date. Select the Assembly you wish to build from the drop-down menu, which will list all of the Assemblies for which you have created a Resource Record Card. Tab to the next field, which is where your specify the Job Series, if you wish to link Jobs together for Group Processing, which is a big time-saver.

On the screen to the right or below, all the input data has been entered. Merlin has entered Logical Start, Finish and Delivery Dates according to the Assembly Definition or BoM data, but has found a Production Line Conflict on the Track or Work Station you have specified, and presented the Warning Screen that you see here, itemising the conflict(s). Having studied this to identify the problem, click the OK button, and Merlin will offer to set a Viable Production Schedule. Say Yes to this, and you will be offered a Revised Production Schedule.

Click Yes to this and your Start, Finish and Delivery Dates will be updated with the new values. You can, of course, choose to keep the desired Production Schedule, and Reschedule the Conflicting Job(s), depending upon your priorities.

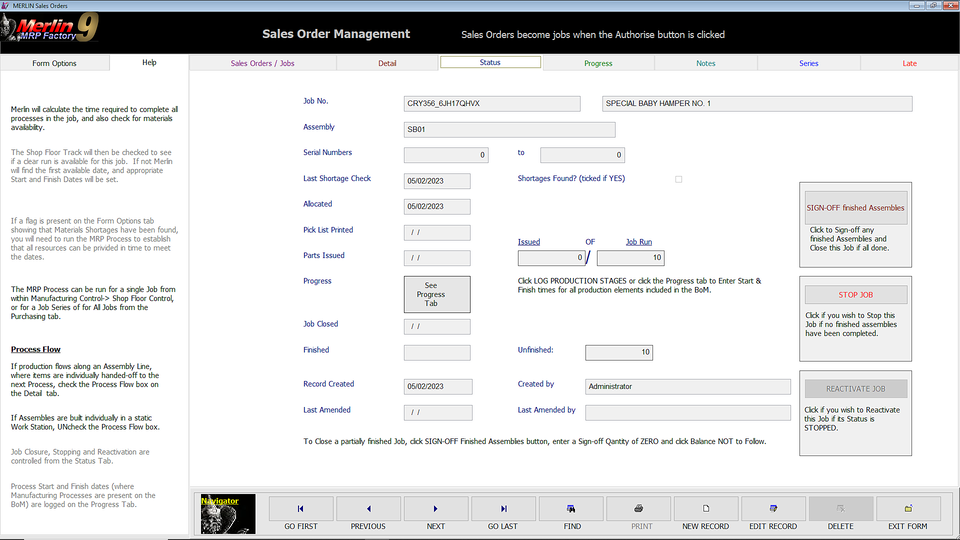

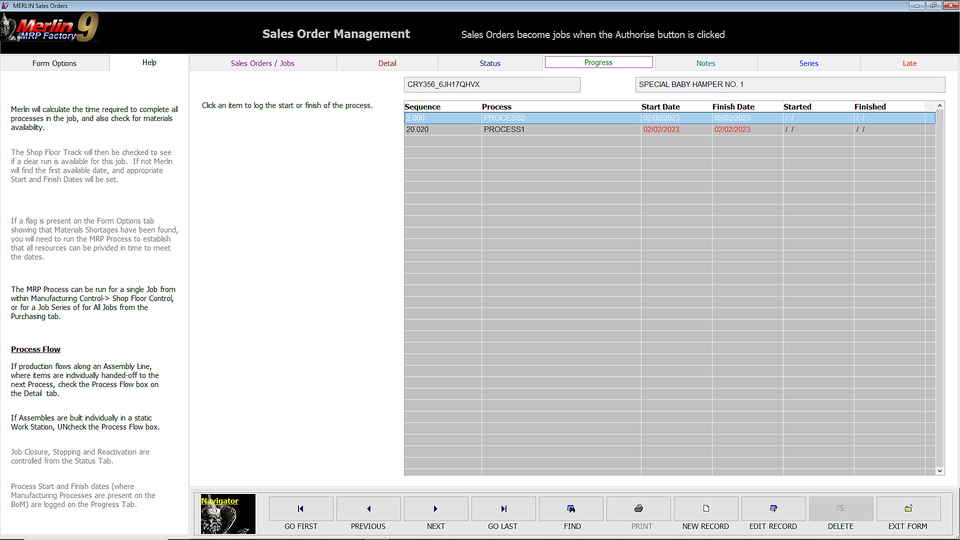

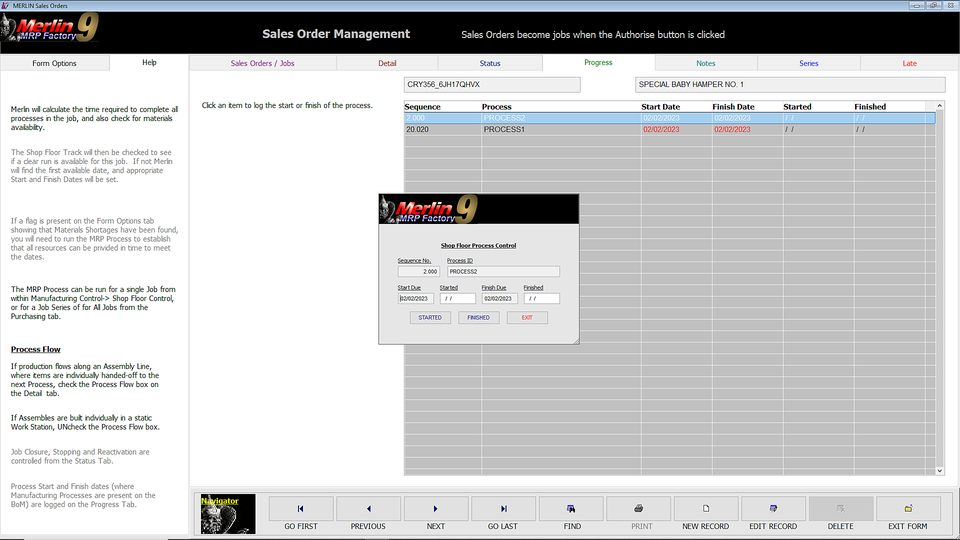

At this point you will have Created a Sales Order, which will not yet be an Active Job. When ready, which may be now, click the AUTHORISE this Job button and your Sales Order will become an Active Job. In case anything has changed, the AUTHORISE this Job button will again check for Production Line Conflicts.

This takes you to Step 3.